Home Page > Technology

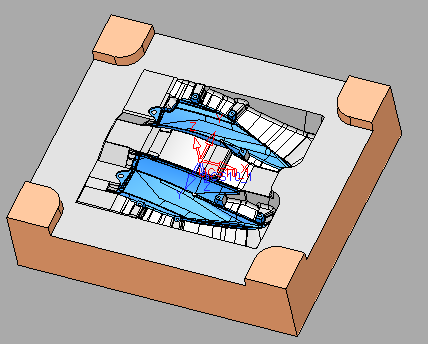

By analyzing the mold flow, it is possible to research in advance and find out expected problems with part and mold design. Through this process, provide the best & nbsp; injection molding parameters for Clients.

By filling, cooling and deformation analysis, find the best optimal injection port system (position, size, type, ...) and optimize the cooling path design in the mold. p>

|

Đăng tải tại

Phân tích dòng chảy trong khuôn

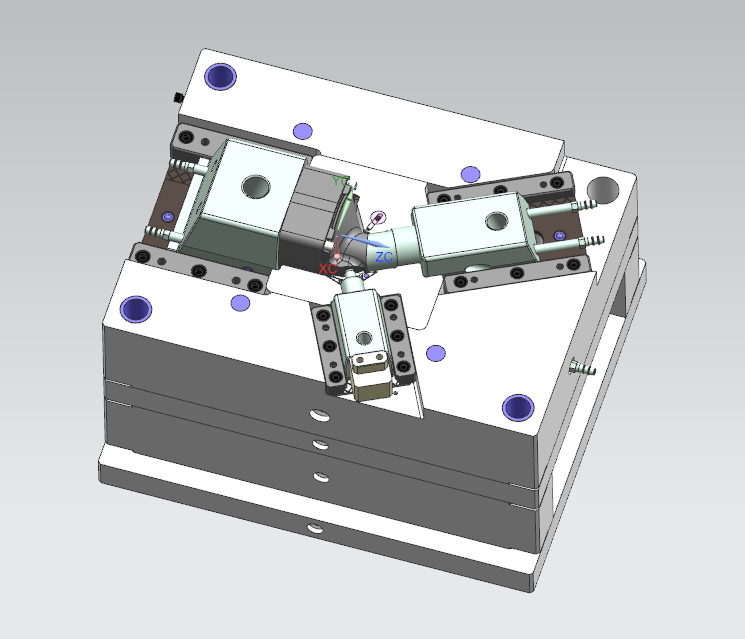

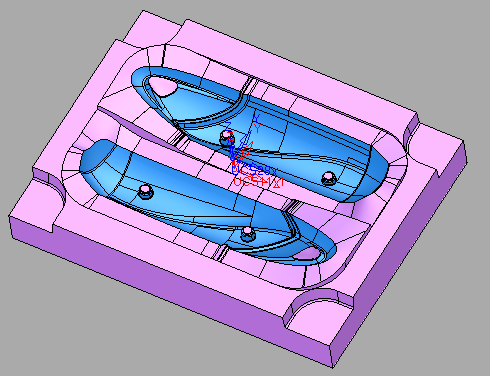

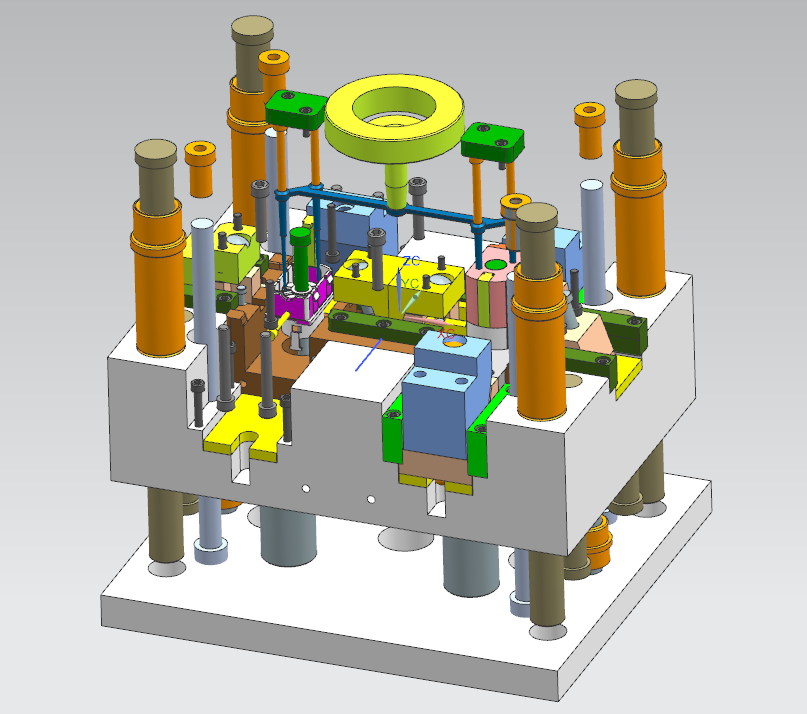

| ♦ We use professional design software. ♦ With full 3D data system of all processes, we can minimize defect time and initial time. ♦ Adopt automatic design system and standard data construction of all kinds of mold parts ♦ Build creativity of Quang Minh by integrating know-how from different customers and accumulating technology. | CAD-Designer- On Hp Workstation

|

|  |  | ||

|  |  |

Đăng tải tại

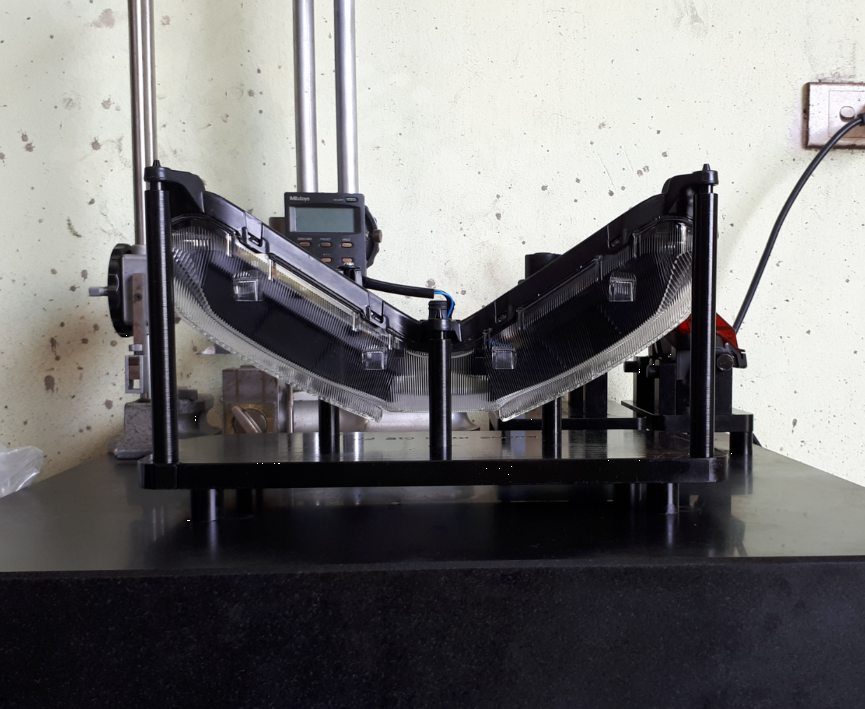

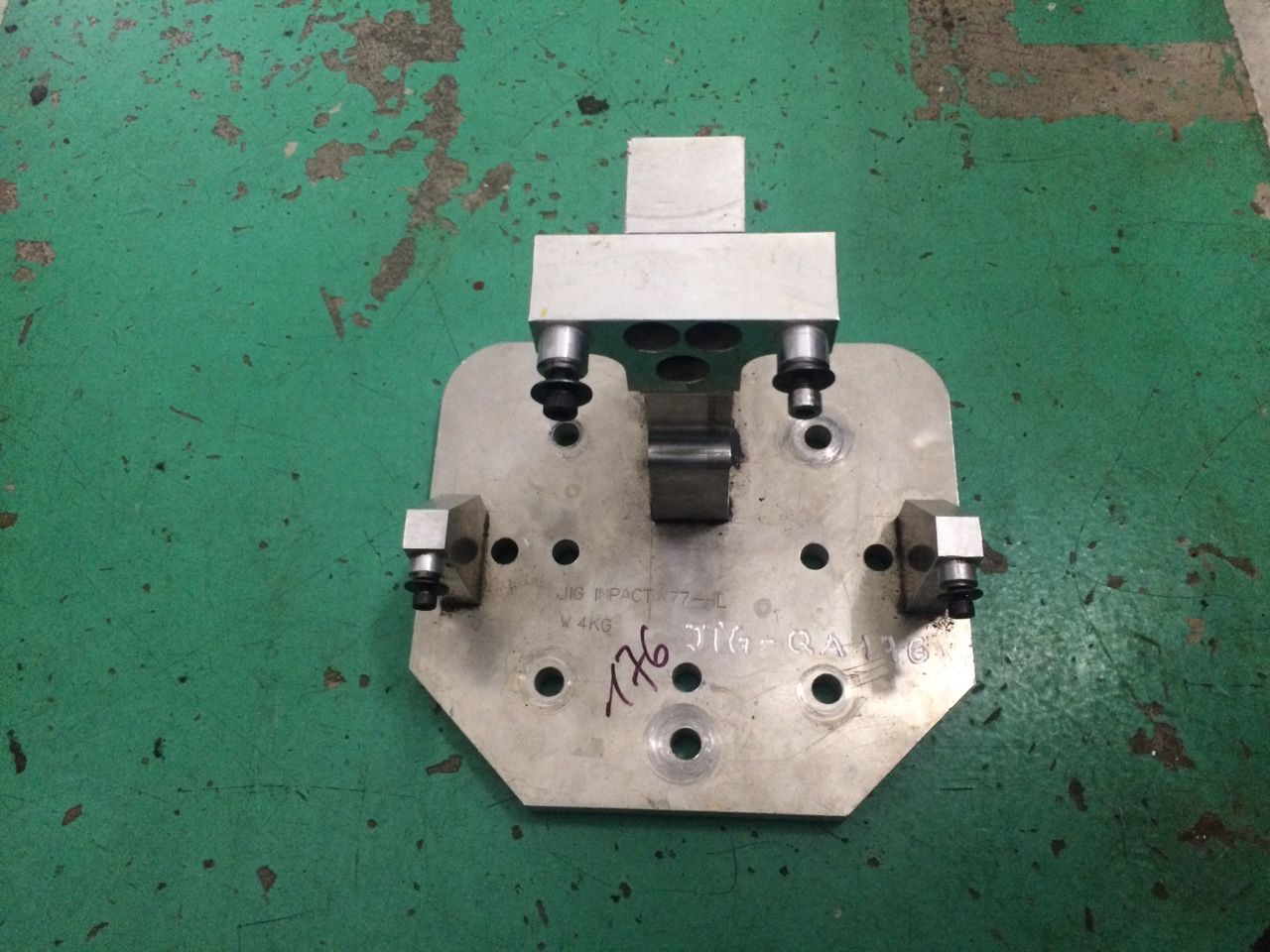

Thiết kế đồ gá và khuôn mẫu

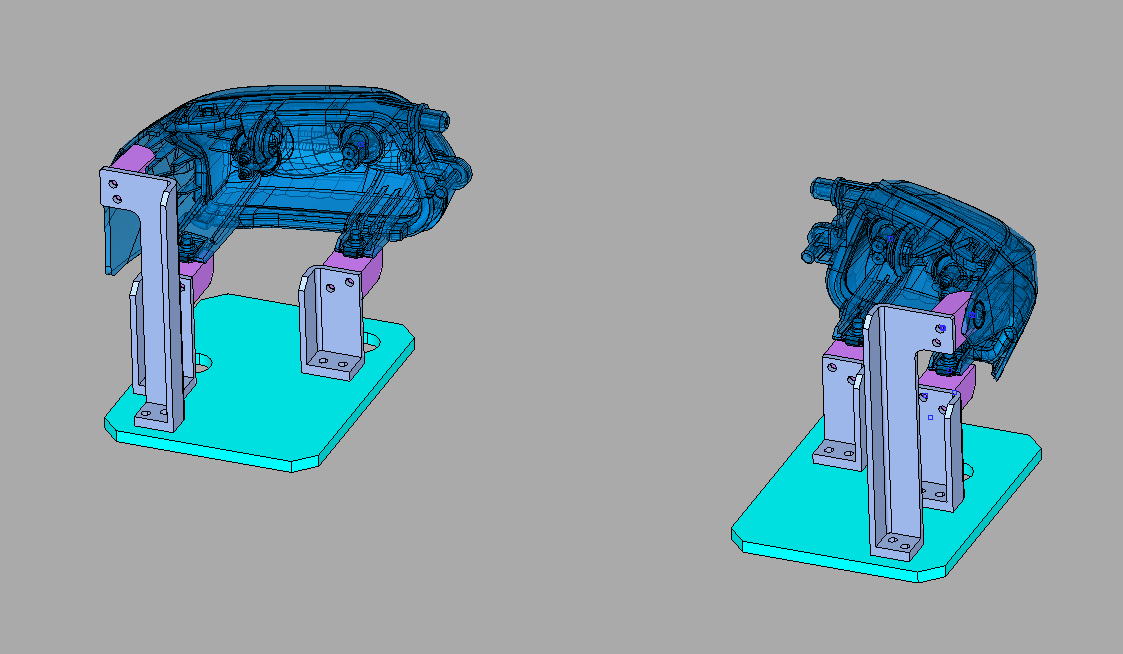

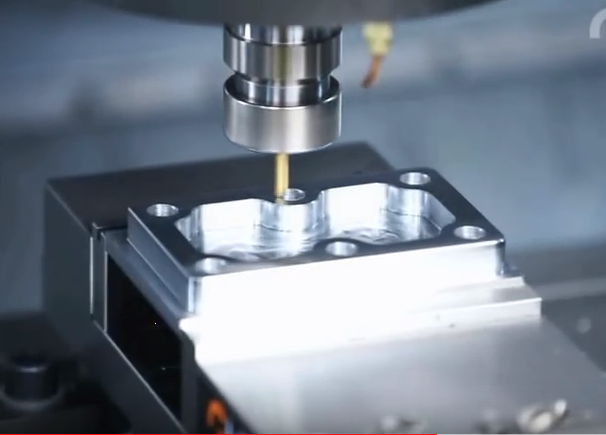

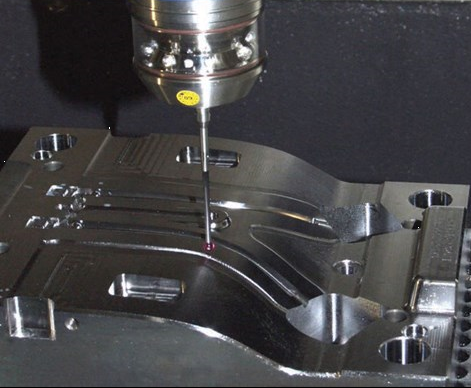

| ♦ High-speed machining / Precision machining toolpaths created by CAM program. ♦ Prevent errors / overload / crashes during machining by computer simulation ♦ Set up a comprehensive 3D data system, automatic tool changing system for CNC ♦ Check molds and jigs after each machining with 3D measuring equipment | CAM-Programer- On Hp Workstation  |

|

|  |  |

Đăng tải tại

Gia công chính xác

|  |  |

|  |  |

|

Đăng tải tại

Lắp giáp đồ gá và khuôn mẫu